Products

Contact Us

- Contact Person : Ms. linda zuo

- Company Name : NIGNBO T.C.I CO LTD

- Tel : 86-574-87928794

- Fax : 86-574-87928794

- Address : Zhejiang,NINGBO,NO. 181 HUIZHAN ROAD

- Country/Region : China

- Zip : 315000

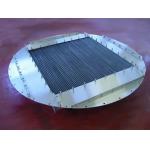

VANE MIST ELIMINATORS

Product Detailed

Related Categories:Other Chemicals

VANE MIST ELIMINATORS

Specifically designed to handle high volume gas flow and reduce fouling, KnitMesh vane mist eliminators are ideal for duties with heavy liquid loads or where the capacity of conventional mesh equipment is exceeded; and can be used at K-values up to 0.45m/s over a broad spectrum of applications.

Also known as chevron or plate type, vane mist eliminators consist of closely spaced corrugated plates that force mist-laden gas to follow serpentine paths. These devices are generally not efficient for mist droplets smaller than about 20 microns, but they are sturdier than mesh pads and impose less pressure drop. Vane arrays can be mounted horizontally or vertically. They are preferred in applications involving high vapor velocities, low available pressure drop, viscous or foaming liquids, lodging or caking of solids, slugs of liquid, or violent upsets. Like mesh pads, vane units are usually round or rectangular. They are sometimes used in combination with mesh pads for optimum performance in special situations. Amistco’s

standard vanes (front cover) are available in metal or plastics and have various blade spacings and profiles. For special requirements, Amistco also supplies curved vanes such as the non-metallic variety shown in Figure 6.

The parallel, chevron construction relies on the principles of droplet inertia, centrifugal force, impingement and gravity. Liquid-laden gas within the vane bundle is forced to change direction several times - which imparts a centrifugal force onto the stream and throws heavier liquid droplets against the wetted walls of the vanes where they are incorporated into the sheet flow of the liquid and drained. Agitation and surface contact also cause coalescence of small droplets within the vanes. As with wire mesh mist eliminators, the KnitMesh vane mist eliminators can be installed either vertically or horizontally. Drainage of liquid from the vane pack to the bulk liquid phase in the vessel is achieved by means of ‘downcomer pipes’.

Vane mist eliminators fall into two categories. Firstly, simple vanes which separate liquid by impingement, coalescence and drainage on the vane surface with no disengagement of the liquid from the gas stream:

Particularly suitable for situations with a significant risk of fouling due to solid particles or high viscosity liquids in the feed

Usually relatively low gas handling capacity

More sophisticated designs provide special separation channels to allow disengagement and liquid drainage from the vane surface:

High capacity designs reduce equipment size

Excellent separation performance even at high gas velocities

KnitMesh vane mist eliminators are capable of high separation efficiency of droplets larger than 10 microns, and pressure drop is usually specified up to 5mbar.

Materials of construction include stainless steel (316L and 304L), Monel¹, Incoloy 825¹, Hastelloy¹ and titanium with other options being available upon request.

Plastic vanes are also available for highly corrosive environments or for simple fume scrubbing applications